Raise3D E2CF, a desktop 3D printer with independent dual extruders (IDEX).

Accurate, Reliable and Accessible. A durable, easy-to-use desktop 3D printer ready to raise accuracy standards, scale production, and add a powerful new manufacturing solution.

The E2CF is an IDEX 3D printer optimized for 3D printing carbon fiber reinforced filaments. This desktop 3D printer is excellent for manufacturing, prototyping, and more.

Carbon fiber reinforced filament has low density, high strength, and it is resistant to corrosion, static electricity, and high temperature. It has potential for a wide range of applications within industries that need considerable strength-to-weight ratio in their solutions, such as the aviation industry and the automotive world. The E2CF is durable, user-friendly, and stable while in operation, delivering accurate prints.

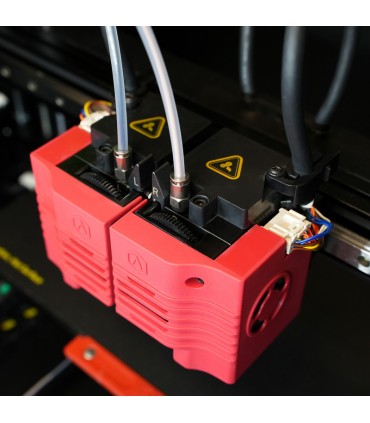

IDEX stands for independent dual extruders, meaning the extruders can operate independently of one another along the same axis during printing to perform more advanced functions. The E2CF is a desktop 3D printer with IDEX. With IDEX, one extruder can remain motionless and off to the side while the second extruder prints the model, minimizing the risk of the nozzle on the motionless extruder interfering with the print job during dual or single extrusion printing.

IDEX can perform two specialized functions, Mirror Mode and Duplication Mode. Mirror Mode prints a model and an inverse of that same model at the same time. It is convenient because it eliminates the need to create an additional design file for the inverse model, and it saves the time that is usually spent printing the inverse model separately. Duplication Mode is synchronized printing, meaning it uses both extruders to print a model and an exact copy of that model at the same time. It can double production capacity within the same timeframe.

Specifications:

| Print Technology |

FDM/FFF |

|

Build Volume (W × D × H). |

Single Extruder Print: 330 × 240 × 240 mm Dual Extruder Print: 295 × 240 × 240 mm |

| Filament Diameter |

1.75 mm |

| Print Head System | Independent dual extruders (IDEX) |

| XYZ Step Size | 0.78125, 0.78125, 0.078125 micron |

| Print Head Travel Speed |

30–150 mm/s |

| Build Plate |

Flexible steel plate with Buildtak |

| Max Build Plate Temperature |

110ºC |

| Heated Bed Material |

Silicone |

| Build Plate Leveling |

Mesh-leveling with flatness detection |

| Filament Run-out Sensor |

Available |

| Supported Materials |

PA12 CF, PA12 CF Support, PPA CF, PPA GF, PPA Support (PET CF and PPS CF Coming soon) |

| Layer Height |

0.01–0.25 mm |

| Nozzle Diameter |

0.4 mm (Default), 0.2/ 0.6/ 0.8/ 1.0 mm (Available) |

| Max Nozzle Temperature |

300ºC |

| Connectivity |

Wi-Fi, LAN, USB port, Live camera |

| Noise Emission (Acoustic) |

<50 dB(A) when building |

| Operating Ambient Temperature |

15-30ºC, 10-90% RH non-condensing |

| Storage Temperature |

-25℃ to +55℃, 10-90% RH non-condensing |

| Filter |

HEPA filter with activated charcoal |

| Machine Size (W × D × H) |

607 × 596 × 465 mm |

| Net Weight |

32.4 kg |

| Gross Weight |

36.7 kg |

| Power Supply Input |

100-240 V AC, 50/ 60 Hz 230 V @ 3.3 A |

| Power Supply Output |

24 V DC, 600 W |

| Slicing Software |

ideaMaker |

| Supported File Types |

STL/ OBJ/ 3MF/ OLTP |

| Supported OSt |

WINDOWS/ macOS/ Linux |

| Machine Code Type |

GCODE |

| User Interface |

7-inch Touch Screen |

| Network |

Wi-Fi, Ethernet |

| Power Loss Recovery |

Available |

| OS |

Embedded Linux |

| Ports |

USB 2.0 × 2, Ethernet × 1 |