ReForm rPLA is likely to be the most sustainable PLA filament on the market. This filament is completely made from renewed materials. There are no virgin fossil- or virgin natural resources added to make this PLA filament.

The design of the formulation of ReForm rPLA is based on the formulation of EasyFil PLA: a proven formulation for printability and high quality 3D printing.

ReForm rPLA profiles are available on the Ultimaker Marketplace. ReForm rPLA is an approved and validated partner material.

ReForm = Sustainability ↑ + Prices ↓

ReForm by FormFutura offers sustainable filaments made from renewed materials only. We have packaged our ReForm filaments in our most sustainable packaging ever. It is our goal to reduce not only our footprint, but also the retail prices. Sustainability and affordability can go hand in hand.

- Renewed materials only, no virgin fossil- or virgin natural resources used.

- All FormFutura packaging is 100% recyclable.

- Spooled on sturdy recycled and FSC certified cardboard spools

- Packaged in recycled and climate neutral cardboard boxes

- Reform is the first filament range that is available on industrial-sized cardboard spools

- Unbeatable retail prices for high-end and sustainable filaments

High-end, sustainable and affordable

ReForm filament is manufactured in the Netherlands according to ISO 9001:2015 standards.

This 3D printing filament is not only friendly for our ecosystem, but also for your budget. Sustainability does not have to come at a higher retail price. ReForm proofs to be high-end, sustainable and also very affordable. Let’s reform additive manufacturing with ReForm by FormFutura!

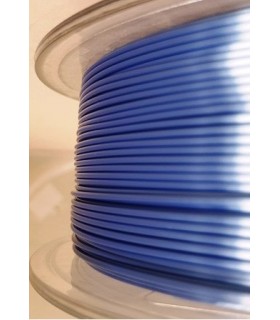

Color intensity

FormFutura ReForm rPLA filament is made up entirely from recycled post-industrial PLA content sourced from the waste streams that arise during the extrusion or our EasyFil PLA filaments. Because of its high recycled content, rPLA filament is not made from a virgin natural PLA compound, but from a homogeneous compound made from a wide variety of colors collected from filament extrusion waste. Homogeneous compound runs can vary in color intensity. This may result in lighter or darker 3D printing filament colors extruded from various homogeneous compound runs. On average two to three homogeneous compound runs are made per year.

rPLA White and Black will always have the same color, as extrusion waste from black and white PLA filament is collected separately.

General printing guidelines*

Nozzle size: ≥ 0.15mm Layer height: ≥ 0.06mm Adhesive: EasyFix Nr. I

Print temp: ± 190 – 215° C Fan speed: 80 – 100% Experience level: Beginner

Heat bed: ± 40 – 60° C Enclosure: No

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers, but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There are a lot of different type of printers, hot-ends and printer offsets that it is extremely difficult to give an overall one-size-fits-all setting.