Refined 3D Printing Experience

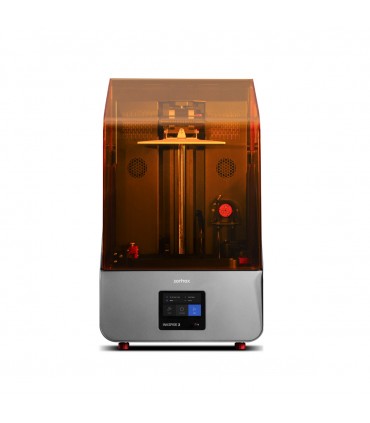

Zortrax Inkspire 2 is a high-end UV LCD 3D printer designed to work with quality resins in a highly automated, streamlined process. Compared to the old Inkspire, it is larger, more powerful, and better in almost every way. The Inkspire 2, along with its complementing post-processing devices, have been thoroughly validated by world’s leading brands like BASF and Henkel to guarantee that each print has mechanical and thermal properties equal to or better than those declared by the manufacturer.

For a true success of your resin 3D prints, a reliable 3D printer is just as crucial as quality materials and post-processing devices. That is why the Inkspire 2 is compatible with best-performing resins from world-leading manufacturers like BASF Forward AM and Henkel/Loctite.

The light engine in the Inkspire 2 has been developed in-house from the ground up. Zortrax engineers designed an array of UV diodes backlighting a monochromatic screen to achieve uniform UV exposure of every single pixel on a large build platform while retaining utmost precision. Therefore, resin 3D models made on the Inkspire 2 have the same, outstanding quality, regardless of whether they are placed in the center or towards the edges of the build platform. Finally, this new light engine is seven times more powerful than a standard UV LCD screen, which makes Zortrax Inkspire 2 compatible with chosen DLP resins.

The Inkspire 2 makes the entire resin 3D printing process simple and clean through automation cleverly implemented in its key components. This makes working with photopolymer resins easier than ever.

The build platform in Zortrax Inkspire 2 is designed to make tasks like removing resin 3D prints or getting rid of leftover resin easier.

The Inkspire 2 3D printer recognizes how much resin is available in the vat and identifies the amount needed to complete the printing process.

The resin vat in the Inkspire 2 is made to solve real issues users have with operating resin 3D printers. It can be easily installed and detached. Curved corners make it easier to clean. An automatic wiper deals with sedimentation in more advanced resins. It is a simple design that works.

Zortrax Inkspire 2 has the same, tried and true, blackout response system that works in Zortrax M Series Plus 3D printers. At all times, the machines store enough energy to save the printing progress whenever a power outage occurs. Once the power is back on, 3D printing can be resumed from the same spot. No more failed prints, no more time lost, no more resin wasted.

The Inkspire 2 supports a wide range of high-end 3D printing resins supplied by world's most trusted manufacturers.

Specification

| Device | |

| Build volume | 192 x 120 x 280 mm |

| Platform | Pre-calibrated during quality control; immediately ready for 3D printing |

| Connectivity | Wi-Fi, LAN, USB |

| Operating System | Android |

| Touchscreen | 4" IPS 800 x 480' |

| External materials | Applicable |

| Supported formats | .zcodex2 |

| Sotfware | |

| Software bundle | Z-SUITE |

| Supported file types | .stl, .obj, .3mf, .ply, .dxf (only 2D models) |

| Supported operating systems | Mac OS Mojave and newer versions / Windows 7 and newer versions |

| Printing | |

| Technoloyg | UV LCD |

| Pixel size 50 | 50 μm |

| Layer thickness | 25, 50, 100 μm |

| LCD screen | 8.9" monochrome |

| Light source | Integrated LED panel (wavelengt 405 nm), ensuring even light distribution across the entire platform |

| Supports | Mechanically removed - printed with the same material as the model |

| Temperature | |

| Ambient operation temperature | 20-40 ºC |

| Storage temperature | 0-35 ºC |

| Electrical | |

| AC input | 100-240 V AC 6.2 A 50/60 Hz |

| Maximum power consumption | 340 W |